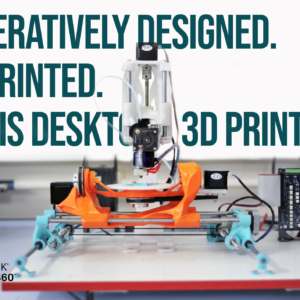

Gen5X is an open-source 5 Axis generatively designed FFF desktop 3D printer. Inspired by the RepRap project, Gen5X explores the next generation of self replicating rapid prototypers, machines that can both design and manufacture their own parts.

Imagine a world where machines not only have the ability to design and manufacture products, but they can also create their own updates and upgrades, without any human intervention. It sounds like science fiction, but this concept is becoming a reality as we continue to push the boundaries of artificial intelligence and robotics. The idea of a machine that can design and make itself is not only intriguing, but it has the potential to revolutionise the way we approach production and manufacturing. In this post, we share with you our research into this emergent world of self-designing machines, exploring what they are, how they work, and the implications they have for our future.

Designing the Gen5X

Generative Design is a process in which a computer algorithm generates multiple design solutions based on a set of constraints and objectives. In the context of self-designing machines, generative design can play a crucial role in enabling these machines to create and improve their own designs.

By leveraging generative design algorithms, self-designing machines can generate and test multiple design variations, optimise their designs based on specific criteria (such as weight, strength, or energy efficiency) and iterate through the design process until they arrive at an optimal solution. This ability to continuously improve their own design makes self-designing machines a powerful tool for innovation and progress.

In the future, AI-prompted generative design could be used to help self-designing machines identify and resolve issues with their own components, such as wear and tear, by suggesting design updates and improvements. This allows self-designing machines to evolve and adapt to their changing environments, using tools such as digital twins and (quite literally) machine learning to further increase their efficiency and effectiveness.

Gen5X was created using Autodesk Fusion360, a free software for students and researchers. You can download all of the Gen5X design files by following the link in our ‘Files‘ section.

Perhaps, in Plato's theory of the forms, there exists the perfect 5-axis FFF 3D Printer, and the Generative Algorithm; a medium between our physical world and that of the ideals.

Making the Gen5X

3D Printing, also known as Additive Manufacturing (AM) and Generative Design go hand in hand in creating cutting-edge products and components, allowing for the creation of complex, customised shapes that would be difficult or even impossible to achieve with traditional manufacturing methods. This combination of generative design and additive manufacturing is disrupting the manufacturing industry with new innovative, high-performance products that are tailored to specific design requirements. By configuring the generative study in Fusion360 to optimise the Gen5X part geometry for FFF 3D printing in PLA, our generatively designed machine parts can be easily replicated on many hobbyist level 3D printers, or even on the Gen5X itself.

What about 5 axis 3D printing?

As you might have noticed, the Gen5X strays from conventional 3-axis machine kinematics to offer an additional pair of rotary axis. Put simply, this is down to 5-axis machines being rather absorbing to watch. Though, there are also other benefits to 5-axis 3D printing, these include:

- Higher precision and accuracy: The additional axes allow the print head to approach the build platform from different angles more precise control and accuracy.

Better surface finish: The extra rotational axes allow for smoother and more controlled movements of the print head.

Greater design freedom: 5-axis 3D printing opens up new possibilities by allowing for more complex and intricate shapes to be printed.

- Improved efficiency: 5-axis 3D printing can reduce the need for additional post-processing or finishing steps, improving efficiency and faster time-to-market for generatively designed parts.

As generative design often results in complex and intricate shapes that require high levels of accuracy in their creation, the increased precision afforded by 5-axis 3D printing leads to higher quality and more accurate prints.

The shift towards 5-axis 3D printing and generative design highlight the growing demand for these types of machines. The Gen5X project aims to provide a lightweight introduction to these methods; it offers those interested a self-taught knowledge in Generative Design, Additive Manufacture, and 5 axis machine programming through making and assembling the machine itself. If you’re less interested in the self-designing element and want to get started with 5 axis 3D printing, check out the Open5x project found here.

Controlling the Gen5X, and Slicing for 5-axis 3D printing

Electronics: The Gen5X is controlled by a RepRap Duet board with a Duex expansion. The Duet is based on open-source hardware and software, allowing for greater flexibility and customisation in terms of control and functionality. This can be especially important for hobbyists and makers who want to experiment with different design and control options. In addition to this, the Duet forums are well supported and have recently dedicated pages to 5 axis control in their documentation.

Slicing: In the context of 5-axis AM, slicing software takes into account the complex movement capabilities of 5-axis machines to create a toolpath. The slicer will generate the necessary commands for the 3D printer to move and extrude material in all five axes, allowing for the creation of highly complex and intricate shapes.

Currently a universal 5-axis slicer for AM is the holy grail in 5-axis AM research. There is excellent progress being made from the likes of Autodesk, Dotx control, and researchers such as the team behind Open5x making 5-axis AM slicing widely accessible.

Future direction

The Gen5X is the first of its kind, a machine that can both design and make itself. The following points give a brief summary of the projects direction.

Firstly, designs are to be set-up parametrically such that machines can regenerate themselves to meet new performance objects, or use different parts, with minimal user input. To give an example, a small subset of readers may have an assortment of spare stepper motors, linear bearings, and 304 stainless steel rods insight. With a parametrically defined design as an input to the generative study, a machine could be generated using the parts that you already have, and not require new ones. A ‘mix-and-match’ machine in just a few clicks. Or, further still, use AI to generate a machine from a photo of your box of parts. Compatibility (at least on the hardware side) would no longer pose such an obstacle to the reuse of many waste electronic components.

Now, what if each part could also capture information about itself? a range of highly accurate sensors collecting machine data in real-time, a digital-twin. With a ‘twin’ of the machine feeding data into a generative study, theoretically, the machine would be able to upgrade itself by learning about how it’s used; before 3D printing their own new and improved parts.

These are the generative machines of the future. The Gen5X project is a first throw at this concept, and aims to serve as a resource for researchers in the fields of computational design, AM, and mechanical engineering. By open-sourcing this project we hope to foster innovation within the community, and invite you to join us in pushing the boundaries of what is possible with generative design, 3D printing technology and AI.

Ric Real

Generative Machine

Acknowledgements and other works

Autodesk. Their software not only made this work possible but also far less of a headache.

Open5X. A particularly big thank you to Freddie for sending the helix G-code shown printing in the demo video. The Open5X project is a big step towards democratising 5-axis 3D printing and I would encourage readers to check it out if you haven’t already.

Dotx control for help with slicing models for 5-axis 3D printing. 5-axis slicer.

Barney Townsend for introducing the RepRap Huxley back in my formative years. And of course, to the RepRap project.

There are many other noteworthy projects and forum contributions that have helped realise this work for which I give great thanks.

Cart is empty

Cart is empty